Technologies

Aluminum structural profile

The aluminum frame elements are made exclusively from primary aluminum, which allows us to ensure stable strength characteristics for our structures.

«Tentery» is the only company in Uzbekistan that operates according to the European quality standard for aluminum, DIN 755, which is superior to the latest Russian GOST 22333-2018. Many Russian companies still use the outdated GOST 4784-978617-18, which is inferior to even GOST 22333-2018. Additionally, we are the only company in Uzbekistan that produces profiles made of alloyed alloys 6005A and 6082. Structures made of these alloys are significantly stronger and more durable than conventional construction alloys such as AD31, 6061, 6063, and others, and can withstand heavy loads. Even with the same cross-section, our structures are up to 20% more reliable.

Anodized structural elements

The increased corrosion resistance of «Tentery» aluminum profiles is achieved through anodization with the highest level of quality, «Qualanod». The European Association «Qualanod» certificate confirms the high quality of anodization and ensures that the manufacturer adheres to strict production and control standards.

The «Qualanod Association» was founded in 1974 in Geneva and now brings together representatives and consumers from all over the world. «Qualanod» regularly checks anodizing processes, controls compliance with standards and issues certificates of compliance to manufacturers who have successfully passed the check.

All «Tentery» profiles are certified according to the «Qualanod» standard.

Quality of awning materials

In our designs, we use tent fabrics from leading global manufacturers. We work with several suppliers, each with their own strengths and weaknesses, and the choice of materials depends on the specific conditions of the tent structure. However, you can be sure that all our materials have stable technical characteristics and are certified according to the necessary standards, including compliance, hygiene, fire safety, and others.

In the standard versions of our structures, we use exclusively non-combustible materials that are non-toxic and do not drip when burned. We also regularly test the tent fabrics to ensure that they meet the stated strength requirements, so that our structures remain reliable and safe to use for a long time.

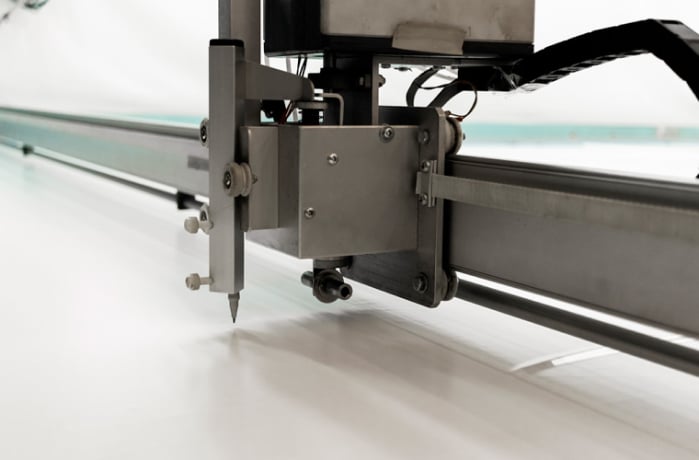

Tent cutting

The Pro Sail cutting complex is an automated system for cutting tent fabrics used in the production of «Tentery» structures.

This system allows you to optimize the consumption of tent materials, minimize waste, reduce cutting time, and increase the accuracy of the process. The cutting accuracy of the parts is 0.1 mm! The complex also provides the option of marking the materials using special pens. The complex is equipped with a 16x3.2-meter cutting table, but it can be expanded with additional tables, allowing for the cutting of parts of any length.

Design and software

«Tentery» engineers use state-of-the-art software to calculate static and dynamic loads on structures, including AutoCAD, SolidWorks, SAP2000, and others. With these tools, we perform strength and stability calculations to ensure the reliability and safety of our structures.

In the design process, various loads are taken into account: self-weight, wind and snow loads, as well as other external factors. The engineer creates a model, and the designers work out all the details to the smallest nuances, taking into account all the requirements and calculations, after which the documentation for the production and installation of the structure is prepared.

It is important to emphasize that the design of «Tentery» structures is carried out by experienced specialists with relevant education and professional skills in this field!

Mounting groups

Our company's employees have all the necessary permits and approvals for high-altitude and rigging work, as well as the right to operate loading equipment and perform tasks of any complexity.

All employees undergo regular specialized testing designed to meet the specific requirements of tent construction, allowing them to confirm and evaluate their qualifications.

We have all the necessary permits for work using rope access, the necessary permits for all types of installation work, strictly follow safety regulations and have extensive experience in the installation of tent and membrane structures. In addition, our employees always come to the customers in uniform and in corporate transport.

Welding of awnings

The welding of tents is performed on a 20-meter automatic TVCH line - Fiab 900. This equipment is used by the world's leading tent manufacturers, and high-frequency welding is the most reliable method, as it is performed automatically and eliminates the possibility of defects. It is worth noting that when two welded tents are tested for tensile strength, the seam is stronger than the material itself.

Ask a question or calculate the cost